Our Operations

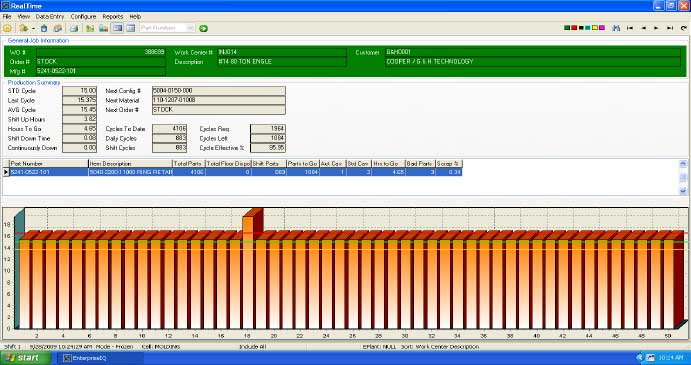

Precise has a complete ERP system that allows us to track product from start to completion. The complete integration of this system throughout the organization allows us to provide a lean and competitive solution for our customers. Operations has integrated all functionality of the manufacturing process, sales, inventory, shipping, maintenance, accounting, quality and resource management. All production machines are tracked through a real-time computer connection that allows us to provide up to the minute data for quality, material control and maintenance of machines and tools. We are able to provide our customers with live information regarding their orders at time of inquiry.

Lean Six Sigma Manufacturing System

Precise Aerospace Manufacturing prides itself on maintaining a Lean Six Sigma Manufacturing System. With this system in place we have been able to cut production costs, improve quality, reduce lead times, and stay ahead of our competitors.

Here are a few highlights from our current system:

- Process Mapping

- Kanban

- 5S Production Workspace

- Real Time Scrap Reporting

- Total Productive Maintenance

- Root Cause Analysis

- Continuous Flow

- Level Scheduling

- KPIs

- Risk Management

- Sampling/Data

- 5 Whys

- Process Capability