Our Capabilities

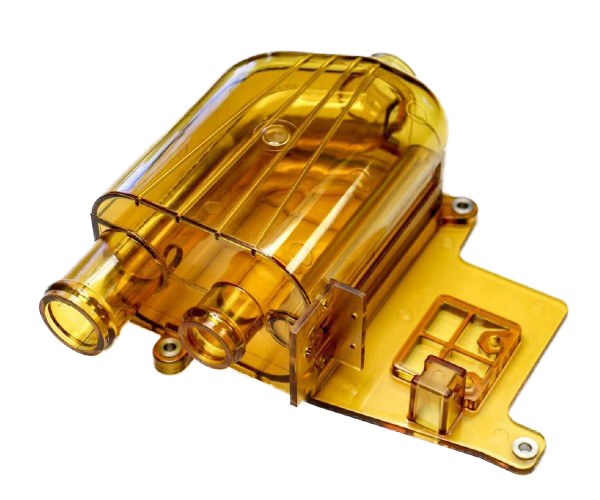

Molding

Vertically Integrated One Stop Solution

Since 1965, Precise has been the premier full-service supplier of Injection, Compression, Transfer Molded Plastic, Four and Five Axis Computer Numerical Control Machining and Value-Added Assembly. Our specialty is close tolerance custom molding for the Aerospace, Defense, Medical, and Electronics industries with complex engineering resin projects, from thermoset and thermoplastic materials. Our customers depend on Precise during the development process for engineering expertise in tool design. We are experts in producing a wide variety of engineering materials such as PEEK and Ultem products.

Our molding machines range in size from 40 to 610 tons. We have experience molding the following products: Ultem, Torlon, PEEK, Polycarbonate, Ryton, Kraton, Acrylic, Phenolic, Nylon, DAP, PPS, POM, ABS, Polysulfone, Styrene, Udel, Stainless Steel, and more.

- Injection Molding

- Transfer Molding

- Compression Molding

- Secondary Machining

- Tool Design/Fabrication

- Mold Flow Analysis

- Aerospace / Defense

- Tight tolerance

- High Quality

- Complex shape

- Part Improvement

- Metal Insert Overmolding

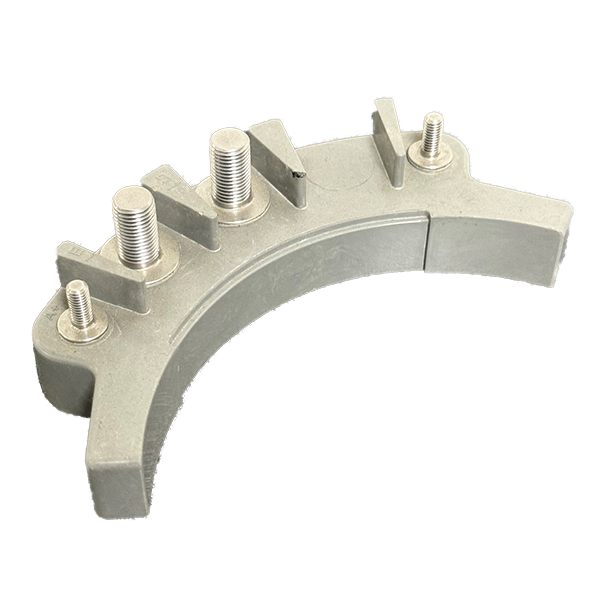

Machining

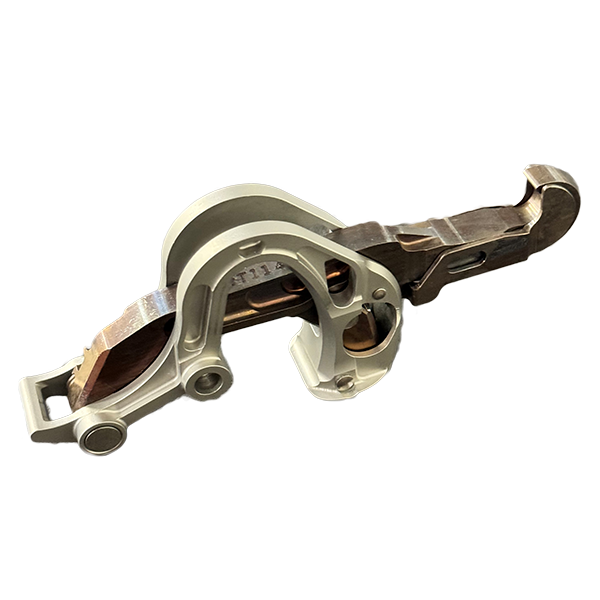

4 and 5 Axis Machining of Plastics and Metals

Precise Aerospace Manufacturing has a fully equipped machining center, capabilities include CNC turning and milling centers. We are investing in our machining center and out capabilities are ever-growing in 4 and 5 axis machining.

The company specializes in complex parts up to 50″ x 26″ x 25″ with tolerances of +/- .0005 and a significant number of subcomponents and machined details.

- OKK

- Yama Seiki

- Miyano

- Fadal

- Haas

- Bridgeport Manual Machines

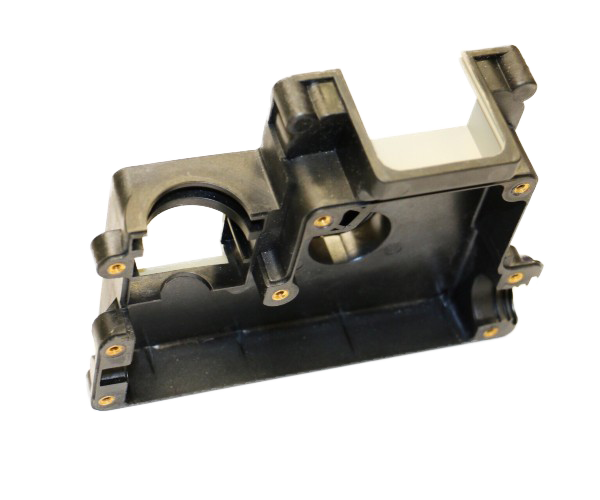

Assembly

Precise Aerospace Manufacturing now provides a highly vertically integrated build-to-print service. This has been a game-changing addition for our customers. Our relentless pursuit of operational perfection combined with an outstanding training program allows us to assemble products made from Precise Aerospace Manufactured machined or molded parts at a fraction of the cost for our customers. We welcome any potential customers to visit our facility and witness best-in-class assembly at Precise.

Precise maintains an extremely clean and efficient operation for our assembly technicians. Our training program is thorough and our documentation and traceability meet the standards of our most demanding aerospace customers.

Assembly ranges up to 20″ x 20″ and can include up to 20 different machined part numbers and sub-components. Assembly includes temperature-controlled curing for epoxy & other plastics.

The following are a few examples of Precise’s current assembling techniques:

- Soldering

- Hardware Installation

- Electro-Mechanical

- Metal - Plastic Ultrasonic Welding

- Sonic Welding

- Bonding

- Rivet Installation

- Hydraulic Pressing

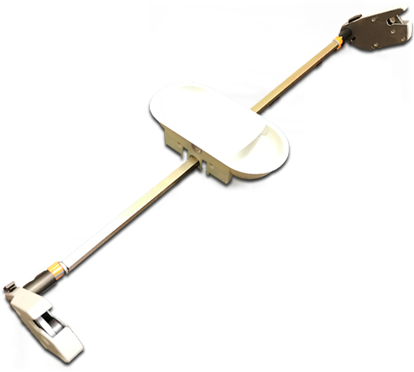

Testing

Precise Aerospace Manufacturing is capable of performing in-house testing as required for our manufactured products, cutting down on customer lead times. We are also looking to expand our testing capabilities to better fit future customer requirements.

Here are a few examples of the type of testing we currently perform:

- Electromagnetic Testing

- Vacuum Testing

- Product Acceptance (Functionality Testing)

- Pressure Testing

- Water Leak Tests

- Force, Torque Test

- Environmental Testing

Non-Destructive Testing

- Penetrant Inspection

- X-Ray

- Magnetic Particle Inspection

Engineering Support

Precise Aerospace Manufacturing has extensive experience on providing our customers with engineering support in developing and improving their product. We have successfully reengineered tooling and parts to better streamline and improve form, fit and function for our customer’s final product. We strive to improve our performance with and for our customers. This capability has made us a crucial asset for many of our customers as we are better equipped to provide valuable information on the improvement of their product.